Door Closer Fitting Template Jig

How to fit closers accurately – everytime, without losing time.

What's the quickest way to fit door closers, accurately?

Here we discuss the pros and cons of paper templates and reuseable jigs. Which one is best depends on how often you fit them, or sometimes the working environment.

The importance of correctly fitting door closers to keep compliant

The highest quality, highly functional door closer can still fail to meet safety compliance if it isn’t fitted properly. Correct fitting of self-closing devices is vital to maintaining safety, compliance, and often product warranty. How the closer is fitted for its fire performance and other quality assurance tests makes this a key feature of its certification and CE/UKCA compliance marking.

This places a responsibility on manufacturers of doorsets, and those installing closers, to follow the closer device manufacturer’s instructions carefully.

Rutland’s door closer template

To ensure the closers can be fitted in the same way as they were tested for compliance purposes, Rutland provides easy-to-follow fitting instructions with every closer. Additionally, this serves as a full-sized (1:1 scaled) template to help with accurate aligning and drilling, helping fitters get the job done correctly – while saving time and headache.

Hardware fitters tell us that without a template to use, it slows them down as they have to measure and mark it out.

The paper templates supplied with Rutland closers help them get it right the first time, and every time. You simply align it with the top of the door, and drill the pilot holes where marked.

However, we understand that while the paper templates supplied free with the door closers are useful, they don’t last long. They can wear out, tear, or fold up just when you need them most – and that can slow the job down.

So we set out to design a jig that makes fitting door closers faster, easier, and more accurate.

Fitting door closers to dozens of doors - use the manufacturer's jig

Many of our customers fit door closers to hundreds of doorsets a week, and for such firms, standardisation is key to maintaining compliance and quality assurance.

While the Rutland paper templates ae famously easy to follow, nothing beats a well-made jig for increasing the accuracy and speed of repetitive production tasks.

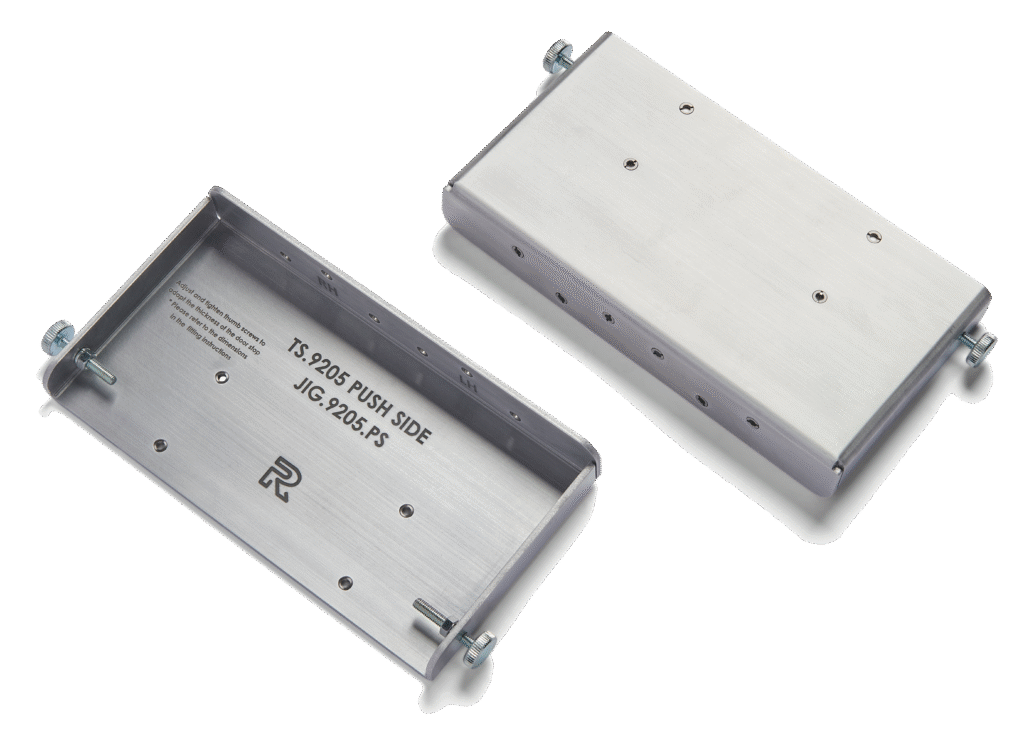

For this reason, Rutland launched a range of jigs to match their door closers. They’re a sturdy tool that helps you get it right first time, every time – aiding proper installation to support compliance, without the hassle.

These specially made jigs help reduce human error by making it easier to drill right, first time and everytime. Fitting each door closer to the same approved spec is crucial for compliance and durability, as small deviations can degrade performance or reduce the closer’s service lifetime.

Features and benefits:

- Non-handed: Works on left- or right-hand doors – saving time on every install.

- Model-specific: Simple, accurate, and designed so you drill the right holes first time.

- Light but tough: Made from lightweight aluminium with reinforced drill holes that’s easy to handle overhead and built to last.

- Factory or site use: Whether you’re on the bench or up the ladder, it’s designed to work where you do.

- Fits different frame types: Adjustable to suit various architrave depths, door stops, and rebates.

- Door compatibility: Standard versions for timber doors and frames, with options available for composite and UPVC systems.

In conclusion, don’t risk voiding your product’s compliance and certification through incorrect alignment of safety-critical hardware such as the closer.

Always fit door closers as per the manufacturer’s instructions, and check that you have the correct template or jig for the closer make and model.

Paper templates are provided with all Rutland door closers for free.

Using a manufacturer’s metal jig is best for maintaining compliance at speed and volume.

It is Rutland’s mission to improve the performance and compliance of doors and their hardware, making it easier and quicker for manufacturers and installers to get it right. With over 20 years’ experience in door hardware, we know compliance starts

with choosing the right closer – and continues with installing it correctly. The jig takes the guesswork out of that process, helping you work faster, more accurately, and stay fully compliant.

If you’re involved in fitting closers to large numbers of doors, either onsite or in the doorset factory, order your jigs today, for faster, compliant and hassle-free closer fitting.