Adjusting a door closer: a how-to guide

Although Rutland is renowned for our range of high-quality door closers, our mission extends far beyond the product itself. Our goal is to enhance compliance and performance at every door. From compliance and testing to maintainance and troubleshooting, Rutland provides detailed support at every stage of the journey to compliant, performing door hardware.

Our range of adjustable door closers are designed to give contractors the ability to fine-tune the door’s operation to meet specific job requirements. This is crucial for addressing a range of factors, including overcoming environmental conditions like excessive air pressures, and adapting to high-traffic areas with frequent use.

A door closer’s purpose

The purpose of a door closer is to reliably shut a door in a controlled manner. Door closers play a vital role in security, fire safety, noise reduction and damage to doors.

Find out more about why choosing the right door closer is important

The importance of adjusting a door closer

Every building (and each door within it) has specific requirements that must be taken into consideration when choosing and installing a door closer – from the location of the door closer on the door, to its surrounding environment. For example, a difference in air pressures on each side of a door could require a power adjustable closer with a higher power setting, but we recommend reducing closing speed to give time for excess air to escape and equalise.

In this scenario, a closer that assists BS8300 is recommended to maintain accessibility for all building users. In a building used by residents with mobility or dexterity challenges, a high-efficiency door closer can help maintain a door’s usability, whilst ensuring the fire door still closes as it should.

Adjustable door closers

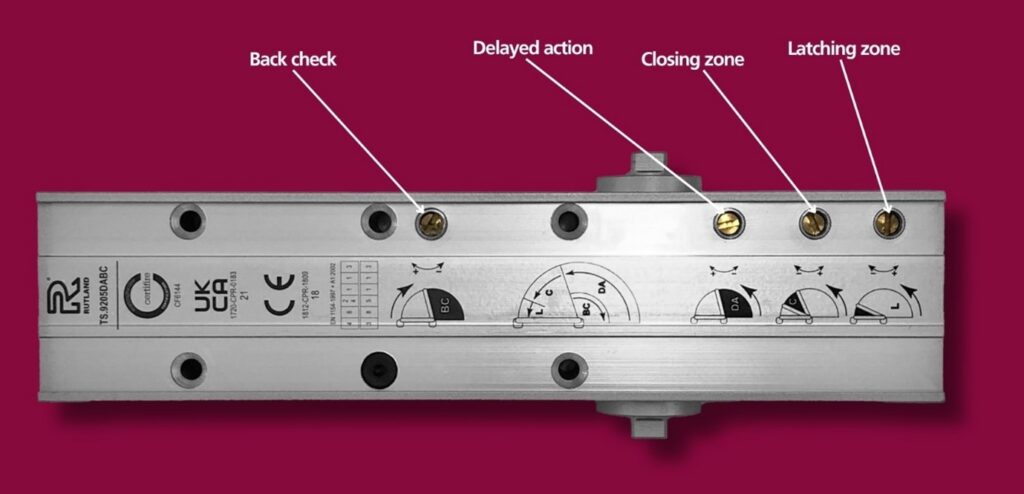

Every Rutland door closer feature a minimum of two adjustable controls – closing speed and latching speed control. Some Rutland door closer models also include further controls:

Power adjustment

Many models of Rutland door closer are adjustable by spring, which means the installer can adjust power without having to move the closer’s position on the door leaf. As mentioned earlier, a power-adjustable door closer gives the fitter options to overcome air pressures and other obstacles to self-closing from any angle.

Back check

This feature helps prevent a door from slamming against adjacent walls or objects when forced open at speed. If the back check function is not required, the feature can be disabled by turning the adjustment valve anticlockwise.

Delayed action door closers make it easier for the people — including those with mobility aids, children’s pushchairs or carrying items — to easily pass through a door fitted with a door closer. From the fully open position, the delayed action feature pauses the close cycle for a few seconds, providing additional time to pass through the door before latching the door shut.

What’s inside a door closer?

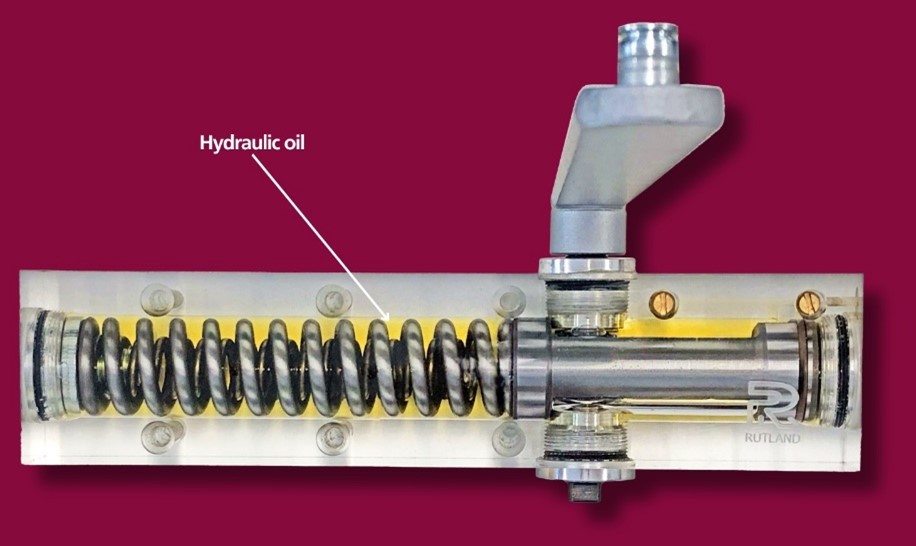

Inside the door closer is a tension spring, piston, cylinder, valves, and seals – all of which are enclosed in hydraulic oil. The action of opening the door compresses the spring. The stored energy in the spring provides the force required to push the piston along its return stroke, which rotates the arm and closes the door.

On power-adjustable models, the power of the door closer can be adjusted with an allen key. By rotating the power adjustment hex screw clockwise, the spring is compressed and loaded with more tension, increasing the force which closes the door.

How to adjust a door closer – step by step

Please note: Specialist tools are not required to adjust a door closer. An allen key provided, and a flathead screwdriver are all you need.

Step one:

Firstly, you will need to gently remove the cover from the door closer. On a TS.9205, TS.9205, TS.11204 and TS.11205 this slides off the main mechanism of the door closer.

Please note: Rutland TS.3204, TS.5204 and Responder 24 models do not feature slide-off trim plates.

Step two:

This step will depend on the situation of the door closer installation. Is the door hard to open? Or are there environmental issues such as excessive air pressures causing problems with the door closing successfully?

If the door is hard to open, it’s likely that the power of the door closer needs to be decreased. On Rutland door closers, the power size is adjustable depending on the door closer installed on the door. For example, the TS.9205 can be adjusted to suit a power size range between EN2 and EN5.

Turning the allen key anticlockwise reduces the potential energy stored inside the spring, reducing the closing and opening forces, in turn making the door easier to open. Ensure that the door can be opened easily but still performs the critical function of fully closing the fire door. Opening the closing speed and latching speed valves with an anticlockwise movement increases the flow rate of the hydraulic oil within the door closer and closes the door at a faster speed.

If there are environmental issues such as air pressures causing issues with the door closing, the first solution to try for this would be to increase the power, and then decrease the speed of the door closer.

Here are some other reasons to you may need to adjust your closer:

- If a door is closing too quickly, turn the closing speed valve clockwise

- If a door is closing too slowly, turn the closing speed valve anticlockwise

- If a door is latching too quickly, turn the latching valve clockwise

- If a door is not latching fully, you may need to increase the power by turning the hex adjustment screw clockwise with an allen key

- If the door is still not latching and increasing the power size, there may be air pressure issues or other conflicts. Start by slowing the closing and latching speed to allow time for air pressures to equalise

If the door is stiff to open, reduce the closer’s power by turning the hex adjustment screw anticlockwise with an allen key to a point where it can overcome any air-pressures, but still assist the user - If the door needs more power but is too difficult to use, consider using approved air transfer grilles (ATG), or upgrading to a fully automatic operator

For further support, please don’t hesitate to reach out to our technical support team on 01246 261491, or use the live chat here on our website.

Relevant articles

Request a call back

Leave us your contact details and we will call you back for a free consultation about your requirements.